WHY WE MUST CHANGE

Committed to a more sustainable future for automotive glazing

It’s no exaggeration that we’re facing one of the biggest challenges in human history. As sea levels rise, forest fires rage and once fertile lands dry out, the effects of climate change become clearer every day. From melting glaciers to increasing storms and from intense heat waves to disappearing biodiversity; we’re all witness to the Earth thrown totally off-balance by getting just a few degrees warmer. Which is why Sekurit Service is truly committed to a more sustainable future for automotive glazing.

What causes climate change?

As greenhouse gas emissions (mainly from fossil fuels) blanket the Earth, they trap the sun’s heat. This leads to a rise of global temperature and as a result, climate change. The world is now warming faster than at any point in recorded history. Warmer temperatures over time are changing weather patterns and disrupting the usual balance of nature. This poses many risks to human beings and all other forms of life on Earth.

Our future is in our own hands

The stakes are clear: we as human beings require a liveable planet – clean air to breathe, fresh water to drink, fertile land to grow our food and as few floods, storms and blazes as possible.

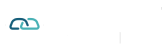

Unfortunately, we haven’t been doing a very good job at securing that future for ourselves, let alone other species on the planet. According to research, we’ve already crossed 6 out of 9 planetary boundaries; environmental limits within which humanity can safely live and develop. As such, we run the risk of destabilising the entire planet’s operating system.

It’s not too late, although we must act fast, act together and act NOW!

The fact that the challenge of climate change is so massive should only motivate us more. At Sekurit Service, we will do our best to make our business more sustainable from our production to distribution, including developing sustainable services for our customers.

A scope for change

Front and centre in the fight against climate change is the reduction of greenhouse gas emissions. These are typically divided into 3 categories, or ‘scopes’ to help measure progress in making the huge reductions that are needed to limit global temperature rises to below 2°C – as stated in the Paris Agreement.

So what are these 3 scopes?

• Scope 1 emissions are ‘direct’ emissions: those that a company causes - such as the manufacturing of our products.

• Scope 2 emissions are ‘indirect’ emissions: from electricity consumption.

• Scope 3 emissions are all other indirect emissions from the whole value chain. They cover the emissions related to sourcing of raw material, use and end of life of the products, upstream and downstream logistics etc.

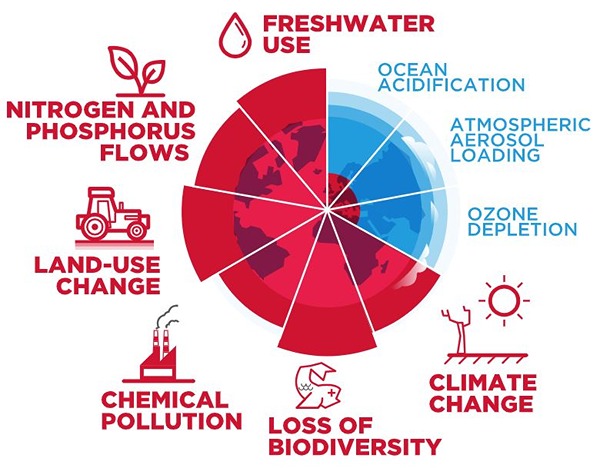

An ambition set in stone

As part of the global Saint-Gobain family, Sekurit Service is guided by a shared commitment to ‘make the world a better home’, which is why our ambition and actions by 2030 (vs 2019) are set in stone. We want to be exemplary on our own operations (scopes 1 & 2) and as a leader we want to engage the whole value chain by also committing on our scope 3:

reduce CO2 emissions by 100% on scopes 1 and 2

30% reduction of Scope 3 emissions

In the coming months, throughout our Made in Europe campaign, we’ll tell you more about the actions we’ve already taken to reduce our greenhouse gas emissions and how we can work together to make our entire industry more sustainable.

Identification & quantification, leading to action & reduction

As part of our sustainability journey we first start by knowing our product’s carbon footprint and source of emissions. It’s all about identification and quantification of our environmental product’s impacts to better know them, allowing us to identify the action lever to reduce them. To do this we use the LCA (Life Cycle Assessment) tool.

LCA is a methodology to quantify the environmental impacts of a product through its entire life cycle (cradle-to-grave) from raw materials extraction to production, including its use and disposal. It is a multi-criteria approach covering resource use such as energy, water, raw material and also emissions associated and output as waste generation. As part of the indicators, we have the most used one named ‘Global warming potential’ also known as carbon footprint.

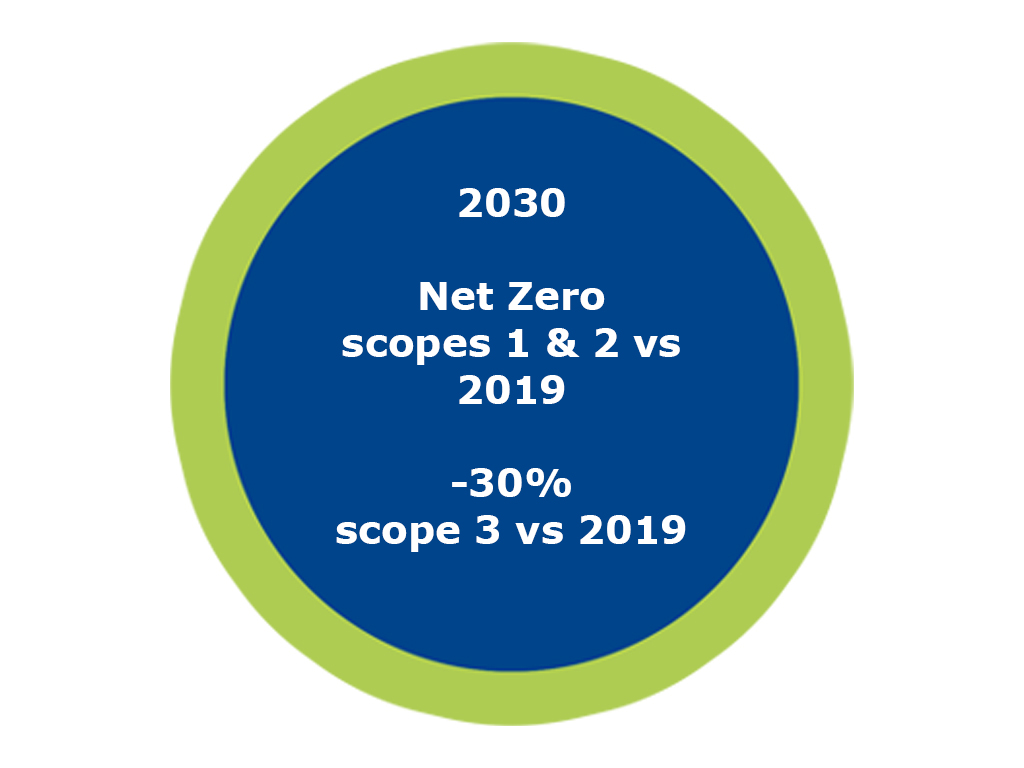

Let’s take a look at the Life Cycle Assessment of a windshield for the aftemarket:

The most important questions in this regard are:

- Where are the windshields produced?

- Where are the CO2-emissions coming from?

- What do we do to improve?

- What are the results?

Let’s look at the carbon footprint figures for our entire life cycle of a Sekurit Service windscreen:

• 54% of the footprint is linked to flat glass manufacturing

• 23% to windshield transformation/processing in our plant

• 19% to our packaging & logistics to the fitting station

• 3% to installation in the fitting station

• 1% to its end-of-life

-> We can clearly see that being Made in Europe – local and close by is a huge driver to reduce the carbon footprint, as it accounts for nearly one fifth of the total emissions of the product.

Our holistic approach to sustainability

To us, sustainability is about much more than reducing our own carbon footprint. That’s why we take a holistic approach to improving the planet for current and future generations. From process optimisation in our plants to a vision of circular economy where waste doesn’t exist and the sharing of best practices with our employees and stakeholders; we’re driven to change the mindset and actions of our whole ecosystem.

---> Follow our Made in Europe story (click for more info):

#2 - Reducing our direct & indirect carbon emissions to zero (more about Scopes 1 & 2)

#3 - Reducing our emissions along the value chain (more about Scope 3)

#4 - Climate change is a collective engagement

--> Read more news about Sustainability and CSR (click for more info):

Sekurit Service Sustainability Roadmap

Saint-Gobain Automotive Glazing Replacement receives GOLD EcoVadis Rating

Gold Award for Saint-Gobain Glass Estonia SE Recognition by the Responsible Business Index (VEF)